Would you like to know how to implement an IATF 16949 compliant Automotive quality management system effectively and economically?

IATF 16949 was developed by the IATF (International Automotive Task Force) to achieve improvements in both the supply chain and the certification process. For most leading automobile manufacturers, certification according to this standard is now a prerequisite for a business relationship. But by implementing IATF 16949, your organization can leverage the opportunity of getting ahead of your competition.

The aim of the automotive industry is clearly the certification of all those involved in the supply chain according to the automotive quality management system standard IATF 16949. This is intended to minimize risks and waste in the supply chain. A key aspect of this automotive QM standard are the customer-specific requirements (CSR’s). Many customers have formulated additional requirements for IATF 16949 and implemented them in the supply chain.

The IATF 16949 specification unifies and replaces existing country-specific standards for quality management systems in the automotive industry from the USA, Germany, France, and Italy, etc.

It defines the requirements for quality management systems regarding the development, manufacture, installation, and maintenance of all automotive products.

The IATF has not only formulated requirements according to a ISO based quality management system for manufacturing suppliers to the automotive industry. In addition, supplemental rules which every supplier of the automotive industry has to implement have been drawn up for the certification process. Also specific auditor guidelines have been developed according to which the auditors have to plan and carry out their audits on the IATF16949 requirements.

GOOD IATF 16949 CONSULTING IS CRITICAL

IATF 16949 advice on the requirements for quality management systems for series and spare parts production in the automotive industry is very important, or to put it another way: Effective interpretations of the “bible” of the automobile manufacturers and their suppliers is very important.

Automotive quality management is a highly developed area of quality management. Due to the very-high production numbers, the platform strategy and the glaring effects of errors, this area has developed rapidly and comprehensively. The global automotive industry places the highest demands on product quality, productivity, competitiveness, and continuous improvement.

In the area of quality management systems, the automotive industry defines ISO 9001 certification as the basis for for achieving a place in the supply chain. Suppliers who have an influence on the product quality and consequently pose a potential risk of errors occurring, should meet a higher quality management standard at the request of the automotive industry.

As a first step, the IATF (International Automotive Task Force) has published the MAQMSR (Minimum Automotive Quality Management System Requirements for Sub-Tier Suppliers). As supplier, you cannot certify against these rules, but to be in compliance with IATF 16949:2016, you absolutely must adhere also to these rules, which represent a kind of “light version” of the generally applicable quality management system standard IATF 16949.

Our IATF 16949 certified auditors and consultants are of course available to help to interpret this of set of rules.

Get ahead of your competition and start to implement IATF 16949:2016 today.

HOW CAN MY COMPANY ACHIEVE IATF 16949 CERTIFICATION?

At JJK Consulting, all IATF 16949 consultants are approved IATF 16949 certification auditors and IATF implementation professionals, who knows what it takes to successfully pass an IATF 16949 certification audit. Our scope of IATF 16949 consulting also includes extensive preparation for the external certification audit.

Separate certification guidelines apply to IATF 16949:2016. Some special “features” compared to ISO 9001 are, for example, the requirements for implementation of a Total Productive Maintenance Program (TPM), enhanced product safety requirements, or the so-called remote locations control, i.e., the support functions that must be evidently monitored during the IATF 16949 certification process. This is just some of the special features of this extensive set of rules.

Before the official certification audit, we usually help suppliers to implement a 100% compliant internal IATF 16949 based quality management system, to ensure the organization is well prepared for their external audit.

Make an appointment and get a Quote today.

IATF 16949 ADVICE ON BEST PRACTICE INTRODUCTION OF A QM SYSTEM When introducing a new quality management system that meets the requirements of the international automotive industry, it is important to involve the company’s employees. The implementation of IATF requirements affects all employees of a company and will be more successful with better informed employees. Their engagement will help to shape the QMS. Our IATF 16949 consultants usually support you as organization in providing transparent information to staff and developing a tailor-made management system.

IATF IMPLEMENTATION PROCESS

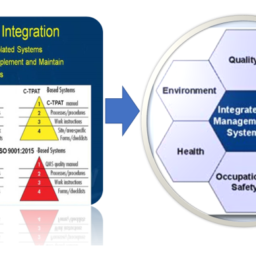

Based on the current processes and any existing management systems in your company, our IATF 16949 consultants will work with you to integrate IATF 16949 requirements into your documented Quality Manual of your system in most cost effective ways. Only what is really needed is implemented, based on the existing management system in place.

This increases the transparency and the first areas of optimization towards compliance become visible. Our IATF 16949 consultants usually interpret the requirements together with you and also implement them together with you and your employees in your company processes in a timely efficient and effective manner.

The required control loops and key figures that are now implemented can now support you in controlling the company processes, which brings high value to your organization. Among other things, the process for internal audits and the advanced IATF 16949 management review process will be developed and implemented. When the actual status is shown transparently and the interfaces are under recognized control, internal audits on the requirements of the IATF standard requirements begin. Thanks to the transparency and the advanced control loops, the company can recognize changes or trends at an early stage and derive measures to react faster than before.

Good IATF Consulting should, among other things, take into account also important factors such as the size of the company, the complexity of the processes and the products or services provided. The characteristics of a quality management system vary with these factors and are then tailored to each company setup by a good IATF 16949 consultants helping to keep cost for implementation down.

Do you have an existing ISO based quality management system and want to upgrade it to an IATF 16949 quality management system and would like to develop it further as integrated management system, or support it with external resources?

Then we are also the right contact. Regardless of whether changes to the management system are necessary because of customer requirements, laws, product, or technology portfolios change, or whether new ideas and perspectives are necessary a experienced IATF consultant can advise you actively on the further development of your IATF management system.

Thanks to the many years of diverse industrial experience of our IATF 16949 consultants, we can provide your organization with a cost and time effective “best-practice” approach and tailor-made “hands-on” solutions.

We can support you with whatever your organization needs:

- IATF process development, optimization or description

- Carrying out an internal IATF system audit

- Implementation of an internal IATF process audit

- Supplier audits and development

- Use of QM methods such as FMEA, APQP / RGA, 8D, MSA, etc.

- Interim IATF QMS management

- Employee training / auditor IATF based training

- IATF based Management review

- Introduction and further development of the key figure system

Get ahead of your competition and start to implement IATF 16949:2016 today. Go ahead and make an appointment HERE.

We offer IATF 16949:2016 Certification – Implementation – Audit Service and Training Services – available in the New York Metro Area and Nationwide Onsite or within cost saving Remote/VPN secure teleconference meetings.

Ready to Explore New Possibilities?

Please contact JJK Consulting at your convenience for an initial consultation on IATF 16949:2016 Certification.

Please contact JJK Consulting at your convenience for an initial consultation on IATF 16949:2016 Certification.

We’ll work with you one on one to determine a roadmap to success.

Call Today: 973-402-5889

#iatf16949consultantnewyersey #iatfcertification #automotivequalitymanagement